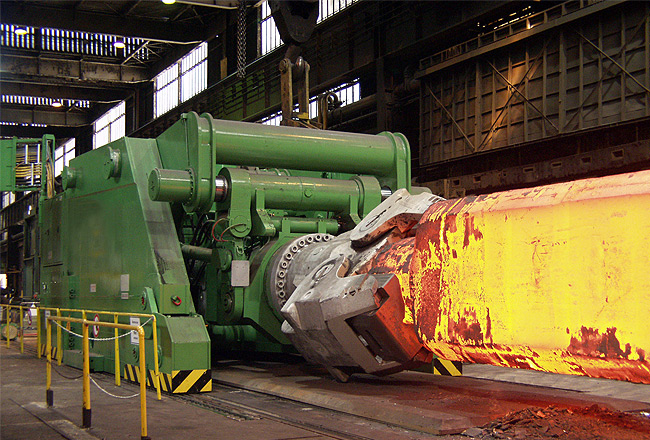

Forging manipulator is a sophisticated piece of equipment designed to handle and manipulate heavy and hot forgings during the forging process. The basic structure of a forging manipulator includes the following components:

- Base Frame: The base frame provides stability and is generally anchored to the ground. It is usually designed to handle the weight and stress involved in heavy forging operations.

- Manipulator Arm: The arm of the manipulator is its main operating component. It is designed to move in multiple axes, providing flexibility in operation. The arm can extend, retract, raise, and lower to position the workpiece accurately.

- Gripping Device: The manipulator arm ends with a gripping device or tongs, which hold the workpiece. This device can be designed to rotate, providing the ability to manipulate the workpiece in a full 360-degree range if necessary.

- Drive System: The drive system, often hydraulic or electric, powers the movement of the manipulator. This system drives the arm’s movements and operates the gripping device.

- Control System: The control system operates the manipulator, directing movements based on operator input. It can be a manual control system or a more advanced automated or semi-automated system using software controls.

- Safety Systems: These include various sensors and guards to prevent accidents during operation. They may monitor temperature, pressure, and proximity to maintain the safe operation of the manipulator.

Forging manipulator is a complex piece of equipment. The specific design and capabilities of a forging manipulator may vary based on its intended use, the size and type of forgings it will handle, and the specific requirements of the forging process it is designed to support.

No comment